| ||

| Products | Services | User Log In | Contact Us | Company |

|

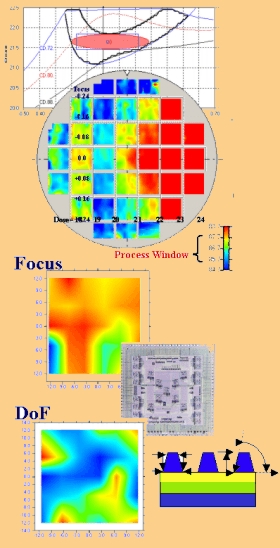

| Typical current analysis graphic outputs also exhibiting full-field best focus and depth-of-focus from Bossung analysis. |

|

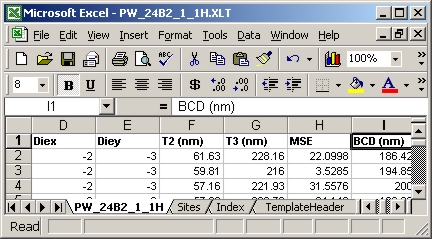

Spreadsheet storage of data and analyses |

|

Weir Macro - data source screen This screen specifies the name of the macro, where data is found and the type of data.

|

|

Weir Macro - Analysis for Process Windows Radio Button at top defines the type of analysis and the variables, culling, method and model. Variables to include in the analysis, control limits and the sites on the field to include are specified. |

Weir Macro - Current Data Display Setup Specifies the graphic and statistics (see below) to include after the most current data set is selected. |

Weir Macro - Statistics & Trend Selection Point & click selection of current and trended statistics. Variable names are taken from data sample and can be defined by the user. |

|

Weir DM - Interactive Interface Interactive 3-button selection for running data. Data listed in the drop-down is sorted by date.

|

Weir DM/DMA Trend Chart Controls are provided for display, method of display, type of data. Average, trend, fitted lines and box plots can be added. |

|

Analysis Drill-Down Mouse-selected field area X-Yplots

|

|

Depth of Focus surface Across field analysis for scanner |

![]()

Automation for any metrology -- Model based characterization & control for setup, qualification, validation and stability of the manufacturing process

Input/ Output

Any film, focus or feature metrology data

CD-sem metrology, overlay, scatterometry, simulation output etc

Z-spin, Line-shortening, PSFM, PGM (Phase gratings), FOCAL, Bossung Focus data

Custom reticle, simulation or aerial image data for Mask Error Enhancement analysis and extended modeling.

output to ASCII files or Microsoft Excel TM Spreadsheets using published output formats

Data and Macro Storage

Microsoft Excel TM Spreadsheets and workbooks

Open system; access to all raw, calculated, modeled and output data.

Overview

Weir DMA automates Weir PW and Weir PSFM user-customized analyses using automated data gathering, external program calling or manual one-button macros capable of intelligent, model-based decoupling of lithographic perturbation sources and process setup/control elements.

The software provides a single-interface environment for automatic acceptance or gathering of data from any feature profile, film or log source of metrology. User-customized outputs are provided in ASCII or Spreadsheet summary. Analysis logging, current analysis displays and trend charts are all user-controlled through user-created Macros. Macros are easily generated from any Weir PW or Weir PSFM analysis using the point-and-click selection interface shown in the screens on the left.

Highly developed Weir perturbation models and statistical component analyses provide unmatched accuracy when correlating process response to simulation and design changes. Weir DMA is a major, single-solution validation component for reticles, simulations and circuit design previously missing from the Design-for-Manufacture (DFM) cycle.

Running Weir DMA

At the conclusion of each non-interactive analysis, the current analysis graphic and statistics defined by the user Macro are displayed for a fixed period and the status and results logged/charted. This fixed period is user-controlled in the clients options setup.

Fully-Automated

Script calling from any server node.

Automated data acquisition from internal timed response

External shelled calls from factor automation or Process Control systems.

Log files maintained for status, analysis and error logging.

Manual Operation steps:

From the Weir DM interface.

Select Weir Macro from drop-down menu

Select Data File from drop-down menu.

Press the "Begin Analysis" Button

Data import is automatic and defined by the Macro. The system is an “open” tool with data stored and easily accessed using Microsoft Excel Spreadsheets. Excel macros/procedures are not used but can be user-added if desired.

Applications

Controlled by user-customized macros from the Weir PW & Weir PSFM products, the Weir DMA package provides initial validation, in-process qualification, setup, control and process-perturbation decoupling for advanced semiconductor lithography applications including:

Reticle Validation

Direct metrology of reticle features; SEM, Ellipsometer etc.

Modeled reticle process and feature uniformity. Includes profile slope variation and etch uniformity when Ellipsometer data is available.

Validation of pattern revisions & new designs.

Reticle Signature library maintenance for later semiconductor process and tool component decoupling.

Reticle Qualification

Process-capability qualification of all reticle patterns direct from wafer measurements:

Accurate, SEM traceable reticle estimation from in-process or focus-dose matrices.

Automated evaluation of Design for Manufacture (DFM) capability that can be both process and tool-set specific.

Re-qualification of in-use full-feature capability of all wavefront-enhanced (RET) Reticle formats including scattering bars, serifs, model-based OPC, and phase-shift mask (PSM) reticles.

Process & Tool Characterization

Setup and qualification of exposure-cell toolsets including scanners & tracks for new installations and post maintenance.

Precision of metrology, process, lens, scan, reticle and wafer stage contributed errors.

Model-based wafer perturbations for bake, deposition, auto-focus and auto-leveling

Model based field, lens-slit and reticle-scan perturbation decoupling.

Intelligent focus-budget models from proprietary pattern such as the Phase-Shift-Focus-Monitor (PSFM), Z-spin constructs or common Bossung analyses.

Automated and extended Mask Error Factor (MEF) Calculation with full-field mapping.

Process & Tool Setup / Stability

Process Window formats:

Full-field, multi-feature full-profile analysis using classic Bossung Plots and advanced control surface models/graphics.

Post exposure bake, hot plate, develop and etch stability.

Film deposition, uniformity and swing curve studies from ellipsometer, scatterometer etc. data.

Decoupling of reticle, process, tool , lens , scan and metrology contributed perturbations to feature uniformity and focus.

Full-Field Focus & Depth-of-Focus field mapping from reticle or Bossugn derived focus as shown in the plots on the left.

Reticle Signature Library

Full-profile, field reticle signatures containing process and uniformity information are stored in the Weir Reticle Library. Reticle signatures are derived from direct metrology of the photomask or through Weir PW analysis of final-image wafer metrology.

Entries in the Library are used to accurately remove reticle contributions from process and tool contributed wafer-level data. This means that process-window calculations, dose response, Depth-of-Focus calculations, Anti-Reflective Coating (ARC) response, reticle-platen distortions and lens/slit & scan characterizations can be derived without the influence of the reticle.

The library elements also provide a historical basis for the re-qualification of reticles when tracking wear-and-tear during production use.

Design for Manufacture (DFM) and Simulator Validation

Direct or manual entry of pattern data from the device design or process simulator.

Removal of Weir Reticle Library signatures from data-modeled process measurements results in the most accurate validation of simulator calculations, DFM efficiency, Mask Error Factor (MEF) and process setup factors in the industry.

Automated Process Control modeling engine for any factory control or Advanced Process Control (APC) system.

Features

Interactive, object-oriented graphics with drill-down capability.

Open and published standard formats of data, input & output.

Automatic mouse-configurable trend-charts, for user-selected variables, raw statistics & modeled coefficients.

Automatic data gathering from any ASCII source and metrology.

User-defined variable names.

X-Y Plots, Histograms, Wafer Contours, Field contours, slit-profile plots, vector plots etc.

Input/output data or mouse selected graphic portions, are easily displayed on spreadsheets.

Graphs can be user-modified using point-and-click mouse commands. Additions of fitted curves, titles, scale, box-plots, labels etc. are all controlled by the user-mouse interface.

System Recommendations

Weir DMA is a compiled application with a full object oriented, mouse-interactive interface. Drill down graphics and spreadsheet analysis supported. Functional on Windows NT and Windows 2000, XP etc., Microsoft Excel is required.

Recommended minimum hardware:

Pentium III, 1 GHz or equivalent CPU

256 Meg of RAM,

1024x768 Graphic Monitor and 30 Mbyte free space on disk for programs.

Data storage may require up to 2.0 Gigabytes additional.

Weir Macros and trend chart data are stored in Microsoft Excel Spreadsheets.

A license for TEA Systems Weir PW© and/or Weir PSFM© is needed for Weir MACRO template creation.

A Network interface for simple data access and automation of data gather is recommended.

Weir PW© provides intelligent film, feature profile and metrology modeling. Weir PSFM provides ASML FOCAL©, Benchmark Technologies PSFM Reticle© and CANON Z-Spin© focus metrology calibration and intelligent response surface modeling.

The Weir Dm© software is an interactive interface for Weir DMA©. This interface is provided with the software and provides interactive macro, trend chart and log file maintenance.

Microsoft Excel is required.

License Basis

Weir DMA products can be purchased on a fixed-node or multi-node basis. Licenses and releases are web maintained.

Weir, Weir PW, Weir DM and Weir PSFM are trademarks of TEA Systems Corp.

FOCAL is a trademark of ASML (http://www.asml.com)

Z-Spin is a trademark of CANON (http://www.canon.usa.com)

PSFM Reticle is a trademark and product of Benchmark Technologies (http://www.BenchmarkTech.com)

Excel is a trademark of Microsoft Corp. (http://www.microsoft.com)

ã Copyright 2005, 2006 TEA Systems Corporation 65 Schlossburg St., Alburtis, PA 18011 All rights reserved. Legal