| Solutions Focus Control Focus may be the most difficult variable to measure. It cannot be directly measured but must be calibrated using special patterns and methods. Validation of metrology is therefore always a consideration and a major element in the analysis. Focus variables range from the optimum focus-offset to be placed into a tool to a model of defocus errors that impart information on lens aberrations, reticle-scanning, reticle platen tilt, wafer tilt, scan-slit travel, reticle bowing, film uniformity and substrate bowing. TEA system products derive optimum and modeled focus from many different commercial sources. Uniquely, they also apply models that go beyond the initial conversion to focus to control and characterize the whole electro-mechanical-optical interactions of the tool and process. If you are working with sub-90 nanometer node processes the number of Reticles employing Enhancements has grown considerable in your process. No amount of simulation can anticipate the level of perturbations introduced by reticle manufacturing or local exposure variations. Also no simulation can estimate the full impact on Depth-of-Focus introduced by RET construct design convolved with lens and process perturbations. Now Weir PW can use wafer-measurements of feature profiles to estimate reticle feature sizes to sub-nanometer accuracy. This capability not only confirms full-field reticle design and manufacture accuracy but also the level of aberrations introduced by each exposure tool in your facility. Along with this full-field contour plots of Optimum Focus, Depth-of-Focus and a Reticle Signature that can be saved in the Weir Reticle Library for improved process and bake setup. Wier PW can optimize and measure the influence of ARC on Best Focus and its variation with dose. Select a product solution according to your needs below or directly click on a product name on the lower-right for more information. |

| |

| ||

| ||

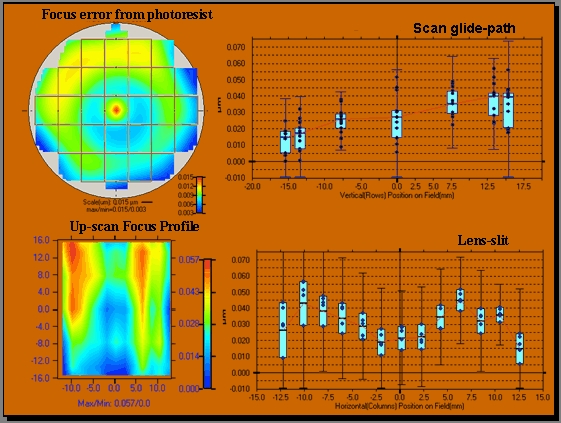

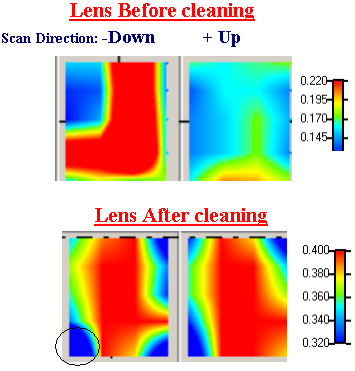

| Depth-of-Focus uniformity variance with scan-direction |