|

|

| Solutions Reticle Analysis The imaging of the pattern reticle to the substrate is perhaps one of the few "magical" elements remaining in Lithography. Aberrational contributors such as lens distortions, proximity, scatter, mechanical and base manufacturing stability of the reticle all support the aura of this mystique. Even the most detailed simulators add in mystic enhancement factors (MEF) that are empirically derived for each process rather than predicted from the physical setup. Reticle variations predominate the critical feature error budget in the process. Until now, even when each feature was directly measure at the mask shop it has been difficult to see their signature variations on the wafer because of the influence of the lens aberrations, films and substrate. Scanners add in a whole new level of contributors through their potential for deformation during the mechanical scan-exposure. Reticles now experience high scan velocities and extreme acceleration during the bidirectional scan process. This often leads to bow-deformation, direction dependant tilt and scan-path-height and pellicle turbulence vibration. Accurate derivations of the contributions of the reticle are critical not only to estimating lens and tool performance but also for deriving a meaningful set of process control variables. Two typical applications include: |

|

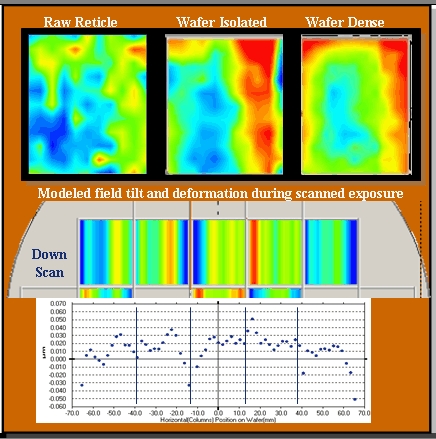

Reticle Signature (Top) and Deformation During Exposure

Top: Wafer errors removed, SEM reticle data is compared against isolated and dense structures on the wafer. . Bottom: Reticles can be tilted and deformed during exposure. This is one row on a wafer with all fields exposed on the "Down" or "-" scan direction. Notice the classic lens "M" shaped signature is both tilted and flattened by the reticle stage. | |

Reticle Qualification

| |

Automated Mask Error Function (MEF) Analysis

| |

| Select a product solution according to your needs below or directly click on a product name on the lower-right for more information. | |