Products

Powerful, flexible, easy to use and never a charge for new or changed metrology imports!*

Download File:

Getting Started with TEA Systems' Products

TEA Systemsí products deliver vendor independent analysis for yield enhancement, process control, systematic error elimination and characterization. Weir product capabilities are unmatched in the industry.

Data is imported and stored in an open format Microsoft Excel workbooks providing full user access to raw, modeled and derived matrices. Automated data reports can be customized and delivered in text or html formats. All products offer enhanced data culling when handling either noisy data or localized disturbances in the process. Culling is both automated and open to user manual control. Data culling can be performed through analysis specific controls and mouse-selected, point-and-click removal or area, wafer, field, site and point specific members. Proprietary mathematical, graphic and modeling engines are uniquely tuned to the highly systematic data populations found in semiconductor manufacturing. Regressions use TEA System's proprietary Singular Value Decomposition, adaptive modeling to provide un-matched accuracy in deriving the control and tuning components that you need to control your process and yields. Graphics Wafer, field or lot vector and contour interactive graphics are linked to the TEA Systems Lot model for full object drill-down capability., 2D, 3D, contour, XYgraphs, Histograms, Trend plots, Curve-fitting, population density curves, BoxPlots and many more graphics are easily created using your mouse and our graphic interface. Point-and-cick data analysis tools provide basic and advanced statistics and precision analyses. analysis tools provide basic and advanced statistics and precision analyses. All analyses can be Weir Macro embedded using our mouse-driven interface to provide two-click data modeling/trending with Weir DM and automated, non-interactive analyses from Advanced Process Control (APC) and factory control systems using Weir DMA.

Data

*

All Analyses use the

Weir Standard Format for data that is stored in Microsoft Excel

workbooks. Workbooks are also used to store reports and additional

analysis-generated data such as focus & dose uniformity. Reports can be

extracted in html format for internet or web reporting. External

metrology data need only be imported into the Weir Workbook the first

time it is used. Follow-up analyses use the Weir Workbook format. Product Details

| |

Product |

Features |

Applications | |

|

|

Vector Raptor

Overlay &

Registration Control

Double Patterning

Feature design response analysis

VR

Matching Interface |

-

See Brochure

- User-customized models

- Advanced adaptive control-surface modeling

- User modified or custom-created

models

- Grid v. wafer

performance

- Full-field,

Lens-slit & Reticle-scan application of models

- "What-if" simulation

analysis

- Analysis Tools

- Drill-down, interactive

graphics and data

- Mouse-generated graphics

and viewing of any data-subset

- Radial wafer dependency

- Comparative analysis by wafer,

feature-design or Double-Patterning layer

- Data types and

Import

- Uses Weir

Standard Format

- Import ASML XY,

Match, FOCAL etc.

- Any size data set up to

65,536 data points

- Any

data format

- Precision calculation

- Covariance calculation

- Data Culling

- Multiple levels of manual

& automated data culling

- Multi-Pattern comparative

performance matching using "Feature Families"

- Remote program calling and

analysis automation using Weir DMA

|

-

Reticle & Photomask

-

Process Control of

overlay & Registration

-

Data encapsulation for

registration signature transmission to wafer-fab

-

New design qualification

-

Process uniformity

analysis

-

In-wafer-process reticle validation

-

Process-Simulation Support

-

Results feedback and

verification

-

Process tolerance

derivation for Design for Manufacture

-

Lot, wafer, reticle,

field, lens and scan signature derivation

-

Feature response

confirmation

-

Characterization &

Optimization

-

Focus and dose signature

response mapping

-

Reticle stage direction

sensitivity mapping

-

Reticle bow mapping

-

Lens and scan-stage setup

-

Matching

-

Pattern performance

characterization for design and Double Patterning applications.

-

Setup

-

Exposure tool stage,

wafer-leveling, scan direction, lens slit performance on profiles,

-

Pre-lot exposure setup

-

Reticle and wafer signature

removal

-

Exposure Tool and Metrology

-

tool matching &

calibration

-

characterization and

critical setup

-

error-budget and

electro-mechanical precision module.

-

performance models and

variable covariance mapping.

-

Yield Analysis

-

Reticle performance

evaluation

-

Simulation of

full-process contribution

-

Exposure; source and

uniformity mapping

-

Film uniformity mapping

-

Performance and process

daily monitor

| |

|

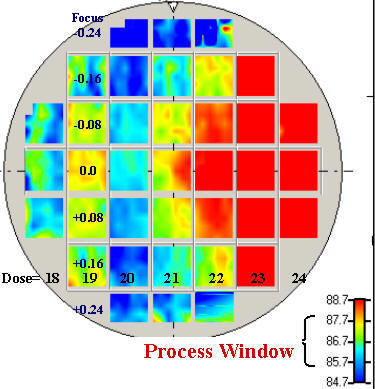

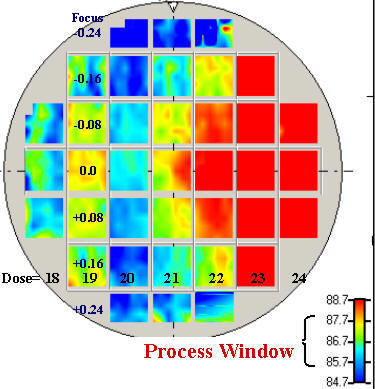

A |

Weir

PW

Full-Profile Feature & Film Response Modeling

Reticle Enhancement Technology response

Advanced Process Windows

Metrology Error extraction

Process, tool and setup error extraction

Process Setup

Reticle Feature extraction

Dose

Uniformity Modeling

Feature-Focus Uniformity

|

-

See Brochure

- Import any metrology.

-

Reticle, wafer, process, temporal, thermal, Flat Panel, yield, ECD etc.

-

Tool and Process Precision

-

Spatial perturbation modeling

-

Metrology validation and characterization

-

Advanced process window calculations

-

Effective Dose mapping (also Exposure Latitude, Depth-of-Focus etc.)

-

Feature Focus mapping

-

Process tolerance studies

|

-

Reticle

- Qualification & Validation

-

Forbidden pitch analysis

-

Proximity correction derivation

-

OPC validation by site

-

Links setup for simulation

-

Process Simulation validation and constant

derivation

- Metrology

-

model validation

-

characterization

-

calibration

-

precision

-

Spatial Modeling

-

Exposure and track-tool setup

-

edge bead control

-

film uniformity mapping

-

Reticle, mean-field and perturbation removal

-

APC, Film, process characterization and modeling from empirical data.

-

Process Window

- Full-field window setup

-

IsoFocal ridge modeling

-

Dose, Exposure Latitude, Focus and Depth-of-Focus mapping

| |

|

A |

Weir PSFM

PSFM, PGM,

Z-spin Reticle Calibration

ASML

FOCAL Analysis

Process

& Tool Focus Uniformity

|

-

See Brochure

- Import registration, overlay and exposure tool metrology

-

Calibrate metrology to focus metrics.

-

Maintain Focus Conversion Template Library

-

Model and visualize a full-wafer, full-field focus response

-

Model focus precision

-

Works with specialty analyses including FOCAL, PSFM, PGM, Zspin and others.

|

-

Reticle Calibration

-

Custom and vendor focus models for data

-

full-field slit and scan focus analysis

-

full-wafer and stage direction focus analysis

| |

|

A |

Weir DM

Script

Automation

Two-click analysis

Trend

charts |

-

See Brochure

- Daily Monitor automation

-

Uses Weir Process Macros to emulate any complex Weir PSFM or PW analysis

-

Two-click data selection and analysis.

-

Automated trend charting of user selected variables.

|

-

Daily Monitor for Focus, Process Window, Metrology, precision, stage tilt, wafer edge-bead etc.

-

Production interface for Weir PW and Weir PSFM complex analyses

-

Analysis automation

-

Trend-plot maintenance.

| |

|

A |

Weir DMA

Script

Automation with remote calling

Automation of input & Output

Any

analysis |

-

See Brochure

- Program or process callable Weir DM for Automation.

- Automated output of data.

- Emailed results and alarms.

- Trend-charting

- APC modeling agent

- Analysis history log.

|

- Automation interface for non-interactive analysis

- APC modeling module

- Factory control automation

- Automated trend plot

- Focus, Dose, DoF, EL%, metrology etc automation.

| |

|

A |

LithoWorks PEB

Thermal

Uniformity analysis of On-Wafer and SensArray data |

-

See Brochure

- Imports feature profile and Thermal Sensor data

-

Hot, chill, bake plate and oven analysis.

-

Link and align and scale data to any metrology source

-

Thermal gradient and energy studies

-

Automated process sequence movies

|

-

Thermal data analysis.

- Bake-plate characterization

-

Chill plate, oven, stage sensor etc.

-

Bake to feature profile and film correlation

-

Energy and temporal thermal mapping.

| |

|

analysis tools provide basic and advanced statistics and precision analyses.

analysis tools provide basic and advanced statistics and precision analyses.