|

||

| Products | Services | User Log In | Contact Us | Company |

|

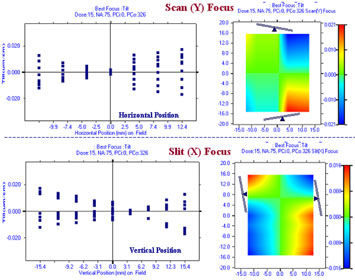

| Photoresist uniformity map showing focus errors across the wafer. Maps such as these have been shown to correlate to ellipsometer measurements. |

|

| Modeled field defocus and edge effects |

|

|

Spreadsheet storage of field-model results. All reports are stored in the Weir data workbook and graphics can be copied to it. Workbook reports and graphics can be saved in HTML format to the internet.

|

|

|

Field-modeled tilt response Top: tilt of the slit during reticle-scan Bottom: reticle scan tilt variation across exposure |

![]()

Automated Wavefront Engineering Software Suite

for Focus Control in the process

- Any uncalibrated or calibrated specialty focus-pattern data as from reticles such as Z-Spin, PSFM, PGM and FOCAL

-

PSFM, PGFM, Z-spin and PGM Focus Monitor TM reticle data.

-

ASML FOCAL

- CD-sem, Optical Scatterometry

- User custom focus-reticle data

- Registration data for focus metrology patterns

Data and Analysis Storage.

- Microsoft ExcelTM spreadsheets and workbooks,

- Report and graphics are stored in the data workbook

- Reports and graphics can be directly saved to web sites using html format

- Full user-access is provided for all raw,

calculated and modeled data.

Modeled scanner field

Weir PSFM is a focus calibration, modeling and control software suite for use in semiconductor development as well as process and exposure tool fabrication control. Weir PSFM provides all the tools needed for characterization and control tasks associated with focus analysis in advanced semiconductor fabrication.

Weir PSFM consists of three modules:

- Weir Layout

- An interactive graphics interface for specifying focus, dose, Numeric aperture, partial coherence and reticle scan direction as a function of the exposure layout on one or more wafers.

- A graphic interface for fine-tuning die size, centering etc.

- Weir PSFM Calibration

- Calibrate measured pattern offsets to exposure tool focus

- The Weir Focus Template library stores calibrations for every feature-site on the reticle

- Verifies reticle design and manufacture accuracy

- Calculates the precision of focus calucation

- Calculate and derive the "Best Focus" field for the lens and reticle. The Best Focus is a measure of the focus errors present in the exposure tools wavefront.

- Model the "Best Focus" of the exposure tool to determine lens aberrations, reticle scan perturbations, bow and tilt of the reticle platen.

- Weir PSFM Fixed Focus

- Use the Weir Focus Template library to convert measured reticle-feature offset data to defocus values across one or more wafers.

- Plot vector, contour and XY plots of the wafer's raw focus perturbations.

- Examine radial and edge bead errors in the wafer process.

- Model whole wafer, field, lens-slit and reticle scan focus errors.

- Calculate height/ focus errors in wafer surface uniformity, bowing, Wafer Tilt, wafer-stage autofocus & leveling.

- Examine reticle scan-direction sensitivity, lens aberrations, field-tilt stability, reticle bowing during loading and scan and reticle deformation during heating.

- Automatically remove average field, lens slit or reticle scan components.

- View "What if" scenarios using simulations to remove focus offset, tilt, bow etc. and focus your engineering efforts to the corrections that provide the greatest advantage.

Use the Weir PSFM software suite to measure and monitor:

- Lens and scanner wavefront behavior

- Wavefront and lens aberration characterization

- Full-field and/or scanner-slit process window characterization.

- Wafer and photoresist uniformity

- Separate wafer and reticle stage tilt

- Reticle-scan stage travel stability

- Astigmatism mapping and

- Reticle-enhancement element qualification.

Weir PSFM automatically imports and converts feature measurements from SEM’s, Scatterometry, Electrical Linewidth Metrology (ELM), other optical and X-ray tools. Automated and manual-interactive data culling methods are fully employed. Output can be on paper or binary format with control surface element-outputs to exposure tools and track.

The Interface

A “Weir” is defined as an “obstruction placed in a stream, diverting the wavefront through a prepared aperture”. The Weir PSFM analysis provides tools to optimize and characterize the image wavefront and it’s aberrations. A full library of user-selected models are provided for the wafer and exposure tools. Model outputs can be controlled and applied to the data to determine the effectiveness of tool corrections through simulation to optimize wavefront performance.

Data import from any data source is supported using

simple windows controls. The system is an “open” tool with data stored

and easily accessed for user extended analyses using Microsoft Excel

Spreadsheets. Worksheet macros are not used for the analysis but the

user can add their own if desired. The analysis will automatically

determine lens and system aberrations for the stepper and scanner.

Weir PSFM is a compiled application with a full object oriented,

mouse-interactive interface. The software is functional on Windows 2000

and Windows XP etc.. Microsoft Excel is required.

ã Copyright 2005,2006 TEA Systems Corporation 65 Schlossburg St., Alburtis, PA 18011 All rights reserved. Legal