|

||

| Products | Services | User Log In | Contact Us | Company |

Vector Raptor Overview Brochure

|

Advanced Setup & Fault Analysis using Comparative & Difference Matching of Processes, Tools & Metrology. (Imports any type or brand of metrology data)

|

Application Notes |

| Scanner Pre-Align & FOCAL focus | |

| Process Window Analysis without models for multi-BARC performance comparison |

Easily analyze process response using Side-by-Side Comparison of response graphics as well as Difference/Subtraction of any characterization or performance data.

VR Matching® provides an interactive, graphic toolset to comparatively quantify and model changes in Inter-Lot or Intra-Lot performance as well as process and tool stability of metrology data. Outputs consist of descriptive graphics, statistics and reports that are stored in the data workbook.

With VR Matching you can see detailed results of process and tool corrections that result from sources such as multiple tool matching, lens heating, process alignment, post exposure bake (PEB) stability and alignment drift. VR Matching allows the engineer to compare:

- the performance of two or more scanners, feature designs, process coatings, recipes etc.

-

Clearly measures single-scanner performance over time or across a lot.

- two or more lots or datasets

- performance within a single, multi-wafer dataset

-

Subtract a reference wafer or lot from a second dataset

-

Subtract an average or selected field from a second dataset

-

Subtract a reference wafer or field from all wafers/fields within the same dataset

-

Save the subtracted data as a datasheet or a new workbook.

After comparison, it's often beneficial to know the exact difference between the Reference and matching data. Contained within this "Difference" is the true correction made to the stepper, the variation in Post Exposure Bake temperature, the relationship between film thickness and other systematic responses that are often hidden in the overall data structure. You can then model the difference-data using the Vector Raptor™ main interface

-

Tool, Process and Systems Matching

-

Process comparative evaluation for Critical Dimension (CD), profiles, film thickness, OPC responseetc.

-

Improved Process Window setup, expansion, extension without using complex Process Window Models.

-

Film, alignment mark, proximity correction and enhancement correction evaluation.

-

Reticle Haze and Lens Contamination detection.

-

Lens Heating, Exposure Drift detection

-

OPC, RET calibration & evaluation

-

Double Patterning tune-up.

-

Reticle validation

-

Performance matching

-

Process Correction validation.

-

Focus Uniformity and Focus Correction Validation

Contents

Raw data as well as data stored in the Weir Data Workbook format can be loaded into the interface. Two datasets must be loaded to perform a matching comparison; the Reference, left side, and the Match, or right-side, datasets as shown in the interface below. The same dataset can be loaded as both reference and matching target to examine stability across a wafer or lot.

The “File” menu contains the tools for loading both Reference and Match data. A history of recently used data files is maintained for ease of access and a “Workspace” menu selection will restore both data sets, Reference & Matching, last used as well as their display, data culling and analysis formats.

Comparative Matching

Performance comparative matching is analyzed by either a side-by-side comparison of the two datasets, figure 1. Reference data is always placed on the left side of the display and the Match dataset is located on the right side.

Data Subtraction Difference Matching

Data subtraction is conducted using the “Difference” interface located under the tab of the same name in the interface shown above. The “Reference” data is always subtracted from the “Match” data in the format:

Difference = Match – Reference

Differences are shown in a separate interface window and include Difference Reports as well as lot, individual wafer, and summary trend graphics when appropriate.

Difference data can be saved and loaded into the Vector Raptor interface for in-depth analysis and modeling. Data can be stored within the “Match” data workbook as a datasheet or in a new workbook using the name and location specified by the user.

Data Fine Format Tools

Loaded data is fine-tuned for display and comparison by using the tools located in the “Data” and “Tools” menus shown in the interface above. The “Data/Data-Units Setup” menu provides an interface to define the units of measure for each variable; mm, um, cm, nm etc. This interface should only be needed if the information is not contained in the raw data file.

Location of the measured sites on the wafer and field are fine tuned using the “Tools/Lot Setup” menu. This interface also allow the substrate size, notch location, die size as well as field centering the on the wafer to be adjusted.

Use the “Orientation” tab to adjust the orientation of the Reference Data Set to the Matching data. This interface provides tools to adjust both the wafer-notch as well as the rotation of the data sites on the wafer.Data Viewing

The data for each graphic or display can be viewed and saved from within the Excel workspace by using the “Data/View Data” menu. Sub-sets of data can be viewed in spreadsheet format by boxing-in the area of the graphic with the left mouse-button and selecting the “Display selected data” menu option from the pop-up menu.

Graph Setup

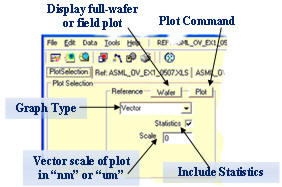

The graph type and its format are specified in the “Plot Selection” tab. Separate controls are provided for the Reference and Matching data plots. Figure 2 shows the control segment for the Reference graphic. Two command buttons are located at the top of the control area. The first of these buttons defines whether a full-wafer plot, as shown in figure 1, or a field-plot is displayed. Clicking the “Wafer” command button will change the plot and the button’s title to “Field”.

“Plot” button: Forces the plot to be recreated and displayed in the associated display window.

Graph Type Combo: The type of graphic is selected from the drop-down combo-control. Plots from this control include:

Selection

Plot Type

Vector

2-dimension vector plots of overlay and radial data color coded to vector magnitude

1-dimension vector plots or single variable X-reg, Y-reg or any variable in the dataset as selected under the Reference or Matching tab controls.

Contour

Contour graphic plots

Radial

X-Y data plots as a function of the radial distance of the measured point from the center of the wafer or field.

X-Y Vertical

X-Y data plots as a function of the vertical (Y-axis) location of the measured point relative to the center of the wafer or field.

X-Y Horizontal

X-Y data plots as a function of the horizontal (X-axis) location of the measured point relative to the center of the wafer or field.

Statistics Check Box: Select to turn on the display of statistics with the data plot.

Scale Field: defines the maximum vector or scale value for the graphic. A zero setting allows the graphic to auto-scale. The graph can be rescaled and edited after creation by right-clicking on the graphic to initialize the graph editor.

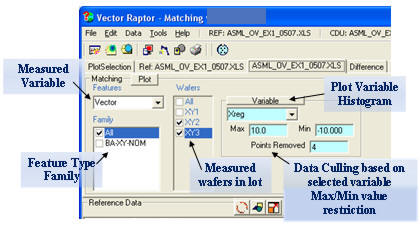

The reference and match lot data selection controls are located in the second and third tabs of the interface. The figure shown below presents the controls used for data subset, culling and variable selection during the “Comparative Matching” of data files. The reference data tab will contain an identical set of controls however the feature, family and wafer entries will reflect those found in the reference lot.

Plot Command: The “Plot” command button will force a re-analysis and plotting of the data.

Feature Selection: The most frequently used control on this page is the “Features” drop-down selection combo. This control defines the variable that will be used in the analysis. Since this example is an overlay data set, the first entry of the control will be “Vector” and the X-reg and Y-reg vectors of the data will be analyzed. To see the individual performance of the X-reg or Y-reg data simple select their variable names from the control.

The Features control will contain up to nine variables depending upon the variables contained in the dataset.

Family Selection: The “Family” control provides a powerful comparitive tool for the evaluation of process and design splits by simply loading the same dataset into both reference and matching interface elements but selecting different family designations for reference and match datasets.

Feature families are defined on the “Sites” worksheet of the dataset. Families allow different feature structures such as overlay mark designs, film stacks, proximity, BARC thickness and via design to be differentiated in the data analysis. The “Family” check-box control provides a method of selecting a sub-set of the analysis data based upon the design components of the targets.

The “Family” data concept is discussed in greater depth in the “GettingStarted_TEAproducts” document referenced at the start of this section.

Wafer Selection: The identification names of the wafers in each metrology lot are presented in the “Wafers” check-box control. Similar to the “Family” control, Intra-Lot comparatives can be performed by loading the same dataset into both reference and matching interfaces and then defining the wafers to include for each analysis segment. Checking a wafer-ID will result in that wafer being included in the analysis.

Culling by Variable Limit

Semiconductor process data populations are always highly systematic and will be more tightly distributed than would be anticipated by the Normal Distribution of a random sampling. Variations from this normal spread result from both feature acquisition and measurement problems of the metrology tool or poor feature definition of the process. This characteristic provides a highly accurate method of data culling for improved performance comparisons. Points that deviate from the anticipated narrow population spread Data points can be culled based upon their distance from the median of the measured population by using the “Variable Cull” control set.

Histogram: A histogram graphic of the selected variable response is generated when the “Variable” button is pressed. Poorly measured data points will extend beyond the short tails of the major population members.

The graph provides an easy method for determination of the proper variable range limit selections for the control. A box-plot at the top of the graphic defines the four quartiles of a proper distribution. These quartiles are specified in the five threshold settings displayed in the lower right of the graphic as “Q0:” through “Q4”. Optical variable minimum and maximum values can be selected from the Q0 and Q4 values or by visual examination of the histogram itself.

Variable drop-down: This combo provides a selection tool for the culling variable. Select the “None” setting to disable this tool and any culling by variable.

Max:/ Min fields: These two fields define the maximum and minimum allowable extent of the data. The values of these fields are set to the dataset maximum and minimum values when a variable name is selected from the Variable drop-down control. Entering a value closer to the median, or “M” value of the histogram box-plot, will result in the exclusion of data points outside of the envelope defined as:

Min <= Data Range <= Max.

Points Removed: This field exhibits the total number of data points removed during the analysis based upon the settings entered into the “Min” and “Max” fields.

Culling with the Mouse

Use the left-mouse button to box in a section of any graphic on the interface. A pop-up menu will appear and you will be presented with options that allow you to view, graph, cull or restore the data points enveloped by the box. Data culling with the mouse is discussed in greater depth in the “GettingStarted_TEAproducts” document referenced at the start of this section.

Comparative Graphic Control

The reference data is plotted on the left side of the interface, the matching data is on the right. Each graph can be edited by right-clicking the graphic with the mouse and using the pop-up interface editor described in the “GettingStarted_TEAproducts” document.

Additional controls are located in the button-bar located on the upper right of the graph window for both the reference and matching data graphs.

Discussion follows for each button, left-to-right on the bar:

Refresh:

This will refresh the graphic without going through the full

calculation. Any changes to variable, culling and other setup parameters

will not be updated.

Refresh:

This will refresh the graphic without going through the full

calculation. Any changes to variable, culling and other setup parameters

will not be updated.

Clone: Creates a duplicate of the graphic and plots the results in a separate pop-up window.

Expand: Expands the current graphic area across the window. The alternate graphic display is eclipsed by this graphic until the “Expand” button is pressed a second time to reduce the area to its original size.

Eye Dropper: Copies the current graphs characteristics such as font size, scaling, vector range color key etc. The Eye-Dropper consists of two buttons, the first eyedropper-button grabs the characteristics, and the second applies the characteristics to the graph. This eye dropper is used to easily copy the graph scale and characteristics to the other display graph so that an easy comparison with equal scaling can be performed.

VR Difference Matching provides an opportunity to see the true effects of drift and changes to the process within a single or across multiple datasets by simply removing the final data set from the response of the reference. Using this toolset you can see subtle changes in the process such as:

· true corrections to lot alignment made by a scanner model update,

· tool improvements obtained after maintenance

· or the influence of lens or reticle heating during extended exposure of the lot.

In the Difference Matching analysis, the reference data previously set up in the Comparative Match interface is now subtracted from the match data. Any data points removed or culled from the two data sets will not be included in the analysis of the difference so metrology and process noise sources do not influence the calculated difference. The controls for the interface are located under the "Difference" tab as shown below. More will be said about these controls later.

Difference Data Requirements

Data requirements are almost non-existent:

· The substrates can be of different sizes.

· Site measurement locations can be different and field sizes can be different.

· Grid-array shapes and die-layouts on the substrate can also be different.

If VR Difference Matching cannot find an exactly corresponding substrate and field location between reference and match layouts then the analysis looks for the nearest sites and interpolates the proper results using localized surface modeling techniques. This capability means that the engineer can reduce the reference data to one field or even one point in a field and the matching data subtraction will continue without error while maintaining the greatest match accuracy.

Reports & Data Saved

Match Difference reports are saved in the Matching Lot data workbook and entered into the “Index” spreadsheet.

|

Worksheet |

Characteristics |

||||||||||||||||||||||||||||

|

MatchReport |

Summarizes the difference of the datasets and the setup controls used. Statistics are presented for each exposure, family and wafer showing the Reference, Match and Difference statistics. Match conditions such as data culling and exposure are also detailed. This report can be saved to other workbooks or an internet “html” format report site using the “File/Save As” commands native to Microsoft Excel. Sample Report Section:

|

||||||||||||||||||||||||||||

|

Difference(filename) |

Optional worksheet containing the difference lot data. This data can then be loaded as a sub-data sheet in the Vector Raptor or Weir Interface. The “filename” variable is the name of the Match Lot so a lot with the name “XYdata” will be saved to worksheet “Difference(XYdata)” |

Difference data can be saved as either a data worksheet in the Matching Lot data workbook or as a separate Difference Lot data workbook. This data can then be loaded into Vector Raptor or the Weir Wavefront Engineering interfaces for additional modeling and analysis.

Difference Match Setup

Referencing the controls shown for the interface in the figure shown above:

Calculate Command: Begins the calculation of the difference lot.

Plot Command: Re-plots the difference graphs without re-calculation of the difference lot.

Point-to-Point: Select this radio-button to force an exact site-location correspondence for difference calculation. If an exact location cannot be found then the site data is not transferred to the difference lot.

Interpolate: If an exact site correspondence cannot be found then the reference data for the site is calculated by modeling the nearest neighbor values. A new reference lot containing the reference metrology signature but now on sites corresponding to the match-lot is created for the subtraction.

Difference Match Graphics

A pop-up interface similar to that of shown below appears after the calculation is completed. This interface contains the graphic, statistics and summary data of the Difference Lot. The tab headings each display a different graphic depending upon the format and subtraction method of the data.

The interface will display only one graph if the match lot contains only one substrate. If the match lot has more than one substrate, as shown in this plot, then the “Difference” tab contains the graphic and statistics for all wafers in the lot. A tab is added for each substrate of the lot and is named with the Wafer ID for the substrate. Each single-wafer tab displays the associated graphic and statistics for the individual wafer. Finally, two additional tabs are then added containing trend plots of the Range and Mean values of each wafer in the lot.

Difference Plot Button Bar

Controls on the button bar allow the screen or graphic to be copied to the clipboard. Data shown on the graph can also be viewed in a spreadsheet format and the eyedropper icons can be used to copy and paste the graph’s scale and axis sizes to other graphs in the display.

A “Clone” button will copy the entire interface to another pop-up window allowing side-by-side comparison of the graphs. This is an especially useful tool when comparing individual wafer graphics.Interpolated Difference Matching

Interpolated datasets can created to allow difference matching even with reference and match-lots that exhibit differing wafer size, field size and site locations as shown in the following figure. In this figure the reference data for both the wafer and field layout values are shown on the left side and the matching dataset is shown on the right side.

When a Difference Match calculation is run, the analysis will be displayed in a pop-up window as shown in the next figure. Since we are interested in viewing the match-data with the reference removed, the wafer and field layouts will follow those of the matching dataset.

Notice the “Interpolated Reference” tab that is now added to the analysis. Since the interpolated reference data cannot be directly viewed in the original interface, this tab provides the missing information by displaying the reference dataset as interpolated onto the site and wafer layout of the Match Lot.

Similar to the point-for-point analysis previous performed, if the Interpolated Difference match lot has more than one wafer then there will be extra tabs containing plots for each individual wafer as well as the Mean and Range trend plots.

Computer system recommendations

TEA Systems Vector Raptor TM is a compiled application with a full object oriented, mouse-interactive interface. Drill down graphics and spreadsheet analysis supported. Functional on Windows 2000, XP etc.. Microsoft Excel© is required.

-

1.2 GHz Dual Core or Greater CPU or similar

-

2 GBytes of RAM,

-

1024x768 Graphic Monitor and 30 M free space on disk for programs.

-

Data storage may require up to 6.0 Gigabytes additional.

ã Copyright 2008 TEA Systems Corporation 65 Schlossburg St., Alburtis, PA 18011 All rights reserved. Legal