Forward to your colleagues.

Vector Raptor

![]()

TEA Systems Announces the release of a new product for

Advanced Overlay Control

in sub-45 nm node lithography with

specialized features for Double Patterning

and Design Matching

Download News: Portable document (pdf) version

On-Line Brochure: Vector Raptor

Portable Document Brochure: Vector Raptor (pdf)

Allentown, PA (USA). July 1, 2007 -- TEA Systems has announced the release of a new and unprecedented software product that enhances the control of overlay and registration in advanced semiconductor manufacturing to minimize it's influence on critical feature dimensions and yield. Vector Raptor is a seventh generation overlay control tool created by the engineers of TEA Systems and is specifically designed to address the unique problems now being introduced by Double Patterning and sub-45 nm process-node technology.

Double Patterning introduces single-layer registration errors that originate during reticle manufacturing, can be amplified during wafer processing and vary with changes in exposure of the individual feature. Current matching and modeling techniques cannot accurately deconvolve the sources of these errors that include a whole new family of overlay and feature-size product yield loss factors.

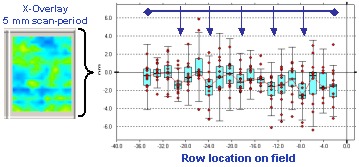

Vector Raptor (VR) provides an object-oriented, fully-interactive graphic interface for advanced control of overlay/registration with matching to any format feature-profile or film data. Common models are provided for all scanner tools and user-designed models can be added using the graphic interface of the VR Model Editor. These features combine to provide a new level of clarity in the precise resolution of each source of error and yield loss and it's correction path.

Vector Raptor uniquely provides a level of capability to the engineer never before experienced. Capabilities that include the ability to resolve the relative response of multiple feature designs, design-response to exposure and reticle-scan noise, the lens-slit signature, various contributions of the wafer-process separate from exposure-tool grid-corrections and the unique contributions of those wafer-process-sensitive perturbations of enhanced reticle designs (RET) that originate in the photomask manufacturing process.

"The new Double Patterning and Double-Exposure approaches to lithographic pattern generation demand drastic improvements in single-layer registration for both photomask manufacture and wafer-process control.", Terrence Zavecz, president of TEA Systems commented. "Reticle pattern-to-alignment-mark and pattern-drift during the plate exposure now combine with plate-processing errors on enhanced reticles to directly influence patterning overlay and feature uniformity during wafer exposure. In the wafer process we see new sensitivities to focus and dose as well as higher correlations between feature size and registration error. The next generation of semiconductors needs a new toolset capable of rapid resolution and precise correction of these error sources. TEA Systems' Vector Raptor addresses this need by incorporating new methods of modeling, matching, simulation and error-source extraction that are needed for yield control and stability in the process. TEA Systems has combined decades of analysis experience with overlay to that of our highly accurate critical feature and profile process tools to release this unique product to semiconductor manufacturing."

Vector Raptor uses TEA Standard Data Format workbooks for storage of all overlay, registration and feature-profile data as well as analysis reports. TEA Systems products provide tools to easily import any format metrology data into the standard format workbooks. There is never a charge for new-format updates. Our products include full support for ASML registration, overlay and FOCAL metrology. Vector Raptor will import and model ANY form of metrology allowing the direct comparison of overlay and feature-size errors.

Vector Raptor is an interactive engineering interface over which the user has full control. The product also includes the process automation power of scripts using Weir Macros. The TEA Systems scripting interface, Weir DMA, provides easy automation of any modeling technique including user-customized reporting with automated Trend Charts of both raw and modeled results.

Applications include:

-

Reticle and Photomask

manufacturing

- Reticle-Manufacturing process control

- Reticle validation and qualification

- Reticle signature encapsulation and reporting

-

Semiconductor Device Processing

- Overlay and Critical Feature Profile signature extraction

- overlay control and pre-exposure setup

- Matching of overlay/registration to feature-profile signatures

- Modeling engine for automation in Advanced Process Control

- Exposure Tool, Metrology Tool and Reticle matching

- Overlay and alignment mark performance matching and response analysis.

-

Process and tool characterization

- Process and tool setup

- focus-exposure-matrix (FEM) response characterization

- Metrology, process, tool and scan precision calculations.

Fixed or floating-node licenses available.

Availability and Pricing

Vector Raptor is available after July 1, 2007.

Vector Raptor and Weir PW products run on windows-based computers using Windows XP,

Windows 2000 or Small Business Server 2003. For more information or to order

Vector Raptor, contact sales@TEAsystems.com.

About TEA Systems

TEA Systems, a privately held corporation since 1988, specializes in advanced, intelligent and adaptive process modeling of the photomask, semiconductor process and it's toolsets. Products from TEA allow the user to decouple process, tool and random perturbations to enhance process setup, control and yield.

TEA Systems products include:

Weir PSFM: Full-wafer/field/scan analysis tool for FOCUS derived from proprietary defocus sensitive features.

Weir PW: Reticle/Full-wafer/field/scan/process data modeling for any metrology with advanced process window capabilities. Product is capable of addressing both wafer and photomask process control.

Weir DMA: Macro Automation interface for Weir PSFM and Weir PW for external calling, automated data gathering or one-button analysis of commonly used sequences. Includes data trending.

Weir TR: A tool to link and correlate profile, film and critical element control to thermal reactions such as PEB and ChillPlate

See us at http://www.TEAsystems.com for a free demonstration or evaluation.

News and Information: http://www.TEAsystems.com/NewsReleases.htm

Contact: Sales@TEAsystems.com or

Terrence Zavecz

Phone: +1 610 682 4146

Cell: +1 610 462 0706

TEA Systems

Corp. | Tel: +1 610 682 4146

65 Schlossburg St., Alburtis, PA USA

* FOCAL is a product of ASM Lithography

![]()